Fused filament fabrication (FFF) cannot 3D print on thin air, although bridging over short gaps is possible. The help of support is required if one layer does not overlap sufficiently the layer immediately below it.

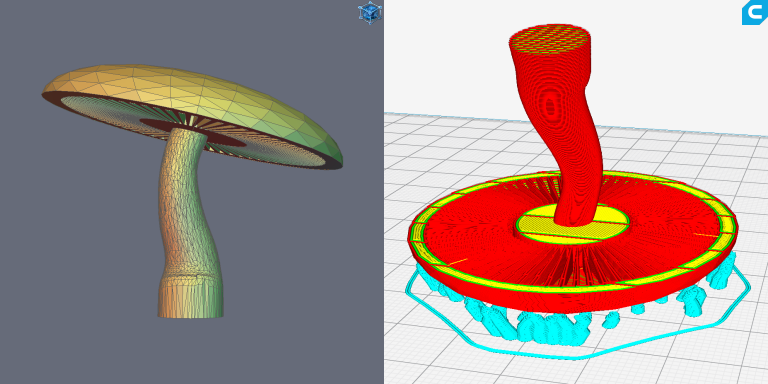

A simple toadstool was modelled in Hexagon 2.5.0.5 and sliced in Cura 3.4.1. The cap was modelled as a squashed hemisphere, without smoothing, with the space between 72 fine gills (each rotated 5°) cut from the underside. The stem was modelled as a cone, bent in two directions by reference to simple Bezier curves, smoothed and manually tweaked. The final model was about 4 cm high and 5 cm in diameter.

For slicing, the layer height was set to 0.2 mm and experimental tree support was used. The support overhang angle was the default 50°. The toadstool was turned on its head for slicing to reduce the support required. A skirt was specified; it seems to help the extruder prepare for printing the object. The model would take 3.5 m of PLA and 70 minutes to print. A extruder temperature of 210° was specified.

The extraneous support was removed relatively easily from the completed print but the upper surface of the cap was of quite poor quality in places. Perhaps, in part, this is because the cap was not smoothed in the original model. The underside was of better quality, with the gills resolved, but where the gills narrowed towards the stem the slicer had introduced an unexpected circular gap. As the underside of the cap had been modelled to be planar perhaps greater care should have been taken in the slicer to ensure it remained horizontal; the aliasing due it being slightly tilted was visible.