ALDI in the UK currently sells the Balco 3D Printer Touch (model HE180021), marketed by Balco Lifestyle and originally manufactured in China by WANHAO 3D Printer. The printer was my first toe in the water of 3D printing.

The printer is very similar to the WANHAO Duplicator i3 Plus (the hardware is said to be somewhere between Mark I and Mark II; Sebastian Andrivet has a repository that provides alternative firmware for the i3 Plus and its clones). Balco Lifestyle appears to me to be a trading name of Winplus Australasia Pty Ltd.

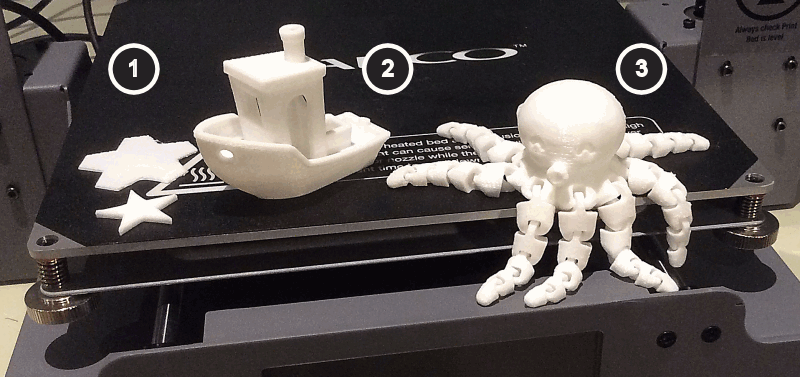

Experiment 1 – Star 25 mm

The printer was easy to set up, with clear written and video instructions. On YouTube, the Teaching Tech channel provided a beginner’s guide from out of the box for a similar, but differently-branded, printer (Cocoon Create Touch).

The printer comes with 100 m of 1.75 mm diameter white PLA and an 8 GB SD card with 44 example .gcode files. Following Teaching Tech, I picked star 25mm.gcode to print and – bingo! – it printed. It came on a raft.

Experiment 2 – 3DBenchy

The Teaching Tech channel also provided a slicing and troubleshooting guide for the same printer. Following the guide, I downloaded the 3DBenchy.stl for 3DBenchy by CreativeTools from Thingiverse.

The printer’s SD card included a installer for a customised version of Ultimaker Cura 3.4.1. I used that to slice the .stl into 0.15 mm layers and produce a .gcode file. It printed and the quality was good. I had specified a bed temperature of 60 °C and an extruder temperature of 210 °C.

For some reason, opening the SD card provided in Windows Explorer on my desktop PC caused a system crash. The same did not occur in Command Prompt or on a laptop. I used a different SD card, once Cura had been installed.

Experiment 3 – Cute Mini Octopus

As a third experiment, I downloaded the Octopus_v5.5_support.stl for Cute Mini Octopus by McGybeer from Thingiverse.

I used Cura to slice it into 0.2 mm layers with a default infill of 15%. However, I added a block in Cura to specify an infill of 100% for the initial layers covering the tentacles. The print took a couple of hours and was successful, with all of the segmented arms working as designed.